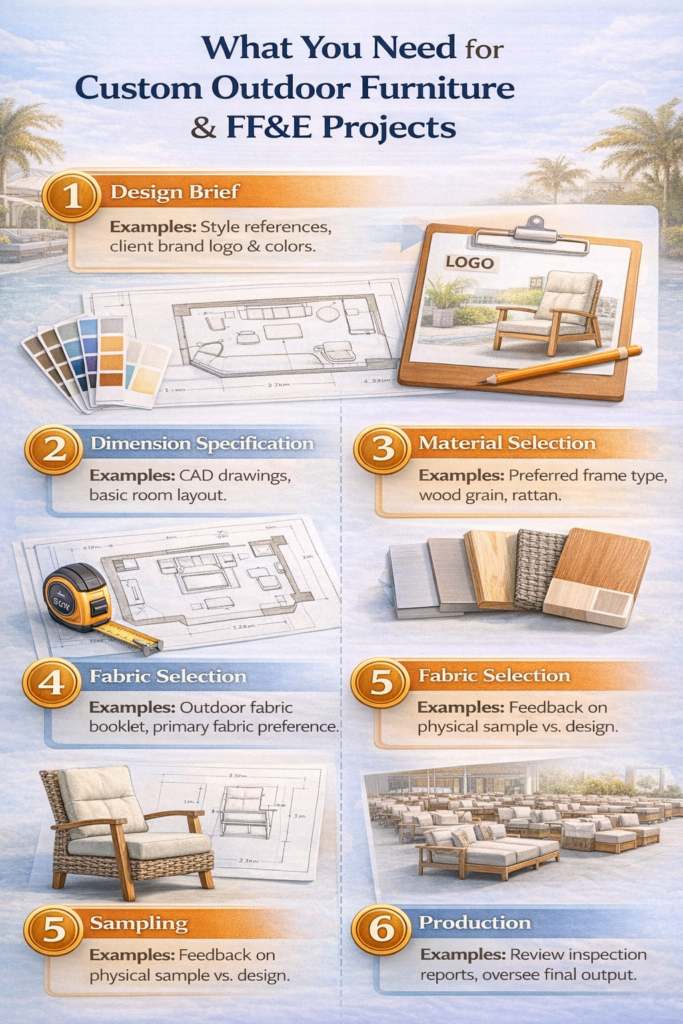

Introduction: Customization Is a Process, Not a Risk

In hotel and FF&E projects, customization is often perceived as uncertain or risky. In practice, custom outdoor furniture becomes low-risk only when the process is clearly defined, documented, and professionally managed.

For commercial projects, customization is not about aesthetic preference alone. It is a structured coordination process that aligns furniture with architectural dimensions, operational use, brand standards, and long-term durability requirements.

In hospitality projects, customization is safest when it follows a repeatable process rather than ad-hoc changes.

Step 1: Designer List and Project Requirements

Every successful custom project begins with a clear designer or procurement list. This list defines intent, not final execution.

When the design brief is clear, customization becomes a controlled translation task rather than a creative risk.

At this stage, clients should prepare reference images, intended usage areas, and estimated quantities. This allows suppliers to evaluate feasibility, structural requirements, and material suitability before dimensions are finalized.

Step 2: Dimension Confirmation and Space Coordination

Custom furniture must respond to real spaces, not catalog assumptions. Dimensions in hospitality projects are driven by circulation, safety clearance, and visual balance.

Early dimension coordination eliminates most downstream changes, delays, and installation conflicts.

Clients should provide layout drawings or space dimensions at this stage so furniture sizing supports both operation and aesthetics.

Step 3: Material Selection Based on Commercial Use

Material selection in custom projects is determined by usage intensity, climate exposure, and maintenance strategy.

Commercial durability is achieved through engineered material systems, not material names.

Suppliers propose combinations such as aluminum frames, teak elements, UV-resistant PE rattan, and all-weather-use fabric to ensure long-term structural stability and surface performance.

Step 4: Fabric and Finish Customization

Fabric and finish decisions connect design intent with operational reality. In commercial environments, appearance must coexist with performance.

Commercial fabric selection balances brand expression with UV resistance, abrasion performance, and regulatory compliance.

Clients confirm colors, textures, and performance requirements to ensure visual consistency and durability.

Step 5: Pre-Production Sample and Approval

The pre-production sample is the most critical risk-control point in custom furniture projects.

Sampling converts drawings and specifications into a physical reference that defines all future production.

Clients review structure, comfort, dimensions, and finish accuracy. Only after approval does mass production begin, reducing uncertainty and misalignment.

Step 6: Mass Production and Quality Control

Once the sample is approved, production becomes a replication task rather than a design exercise.

Quality control ensures that every unit produced matches the approved reference in structure, tolerance, and finish.

Clear documentation and inspection standards protect consistency across large quantities.

Custom Furniture vs Ready Stock: The Real Project Difference

Ready-stock furniture prioritizes speed and availability. Custom furniture prioritizes alignment with space, brand, and operation.

In hospitality projects, customization reduces long-term compromise even if it requires more upfront coordination.

Why Customization Does Not Mean High Risk

Customization itself is not a risk. Unclear processes are.

When responsibilities, approvals, and specifications are clearly defined, custom projects achieve predictable outcomes.

This structured approach supports capabilities outlined in Customization & Capabilities and preparation guidance in How to Work With CG / Inquiry Checklist.

Final Thoughts: Customization as a Strategic Advantage

For hotel and FF&E projects, customization is not a luxury—it is a coordination strategy.

Well-managed customization improves fit, protects brand consistency, and reduces long-term operational risk compared to off-the-shelf solutions.

When the process is clear, custom outdoor furniture becomes one of the most reliable tools in hospitality project delivery.